IQF Systems – IQF Cold Storage

Cold storage facilities equipped with Individual Quick Freezing (IQF) systems are revolutionizing the food preservation landscape. This comprehensive overview delves into the technical intricacies of IQF-equipped cold storage, shedding light on its advanced freezing technology, benefits for various food items, and its pivotal role in enhancing the food supply chain.

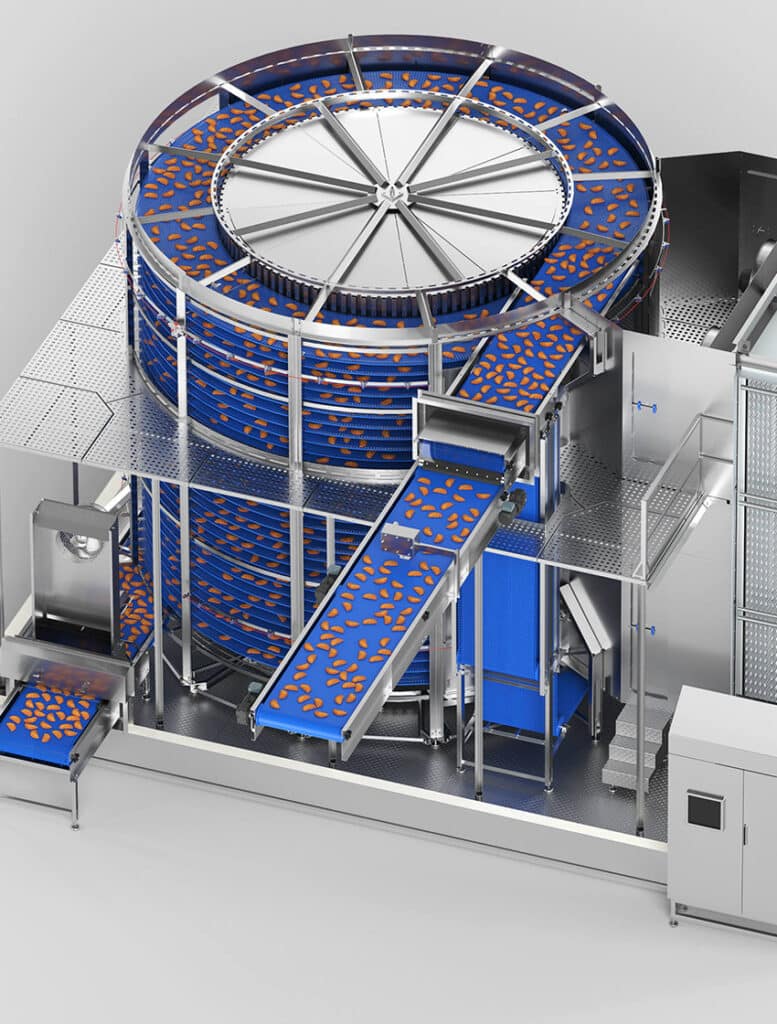

Advanced Freezing Technology: IQF systems employ cutting-edge freezing technology that rapidly freezes individual food items. Unlike traditional freezing methods, where items freeze together, IQF ensures each piece freezes individually, preserving texture, flavor, and nutritional value. This technology involves a quick blast of cold air that forms tiny ice crystals on the outer layer of the food, allowing for rapid and uniform freezing.

Benefits for Various Food Items: The IQF system’s versatility extends to a wide range of food products. Fruits, vegetables, seafood, poultry, and even delicate pastries can benefit from IQF freezing. The system’s ability to freeze items separately prevents them from sticking together, maintaining their integrity and facilitating portion control.

Optimizing Food Supply Chain: Cold storage facilities equipped with IQF systems play a pivotal role in optimizing the food supply chain. By quickly freezing products individually, IQF enhances the shelf life of food items, reducing food waste and allowing for extended storage periods without compromising quality.

Precision in Temperature Control: IQF systems boast advanced temperature control mechanisms. They maintain precise freezing temperatures, ensuring that food items freeze uniformly and quickly. This precision not only preserves the quality of the products but also prevents the formation of ice crystals that can alter texture upon thawing.

Energy Efficiency and Sustainability: IQF-equipped cold storage facilities are designed with energy efficiency and sustainability in mind. These systems are engineered to minimize energy consumption while maximizing freezing efficiency. By reducing freezing times and energy usage, IQF contributes to a more sustainable food preservation process.

Customized Solutions for Food Preservation: IQF systems offer customizable solutions for various food types. Whether it’s delicate berries, seafood, or bulk poultry, IQF technology can be tailored to meet specific freezing requirements. This flexibility ensures that each product is frozen optimally, maintaining its quality and extending its shelf life.

Enhancing Quality and Convenience: Cold storage facilities with IQF systems provide superior quality and convenience for consumers. The ability to quickly freeze individual food items ensures that consumers receive products that are as close to freshly harvested or prepared as possible. Moreover, IQF-frozen items are easy to portion and use, reducing preparation time and enhancing culinary experiences.

In conclusion, cold storage facilities integrated with IQF systems are at the forefront of modern food preservation technology. Through advanced freezing techniques, precision temperature control, and sustainable practices, these facilities uphold the quality and freshness of a diverse range of food items. By optimizing the food supply chain and reducing waste, IQF-equipped cold storage facilities contribute to a more efficient and sustainable food industry.