FREEZE DRY MAKİNELERİ- FRZ-350

İnovasyon alanında, 350 kg’lık Freeze Dry Cihazı, teknolojik harikanın ve dönüştürücü potansiyelin zirvesi olarak ortaya çıkıyor. En son teknolojiyi benzersiz işlevsellikle birleştiren bu cihaz, koruma sanatında devrim yaratmaya hazırlanıyor. Bu makalede, 350 kg’lık Dondurarak Kurutma Cihazının karmaşık teknik ayrıntılarını incelerken, sayısız endüstride koruma uygulamalarını yükseltme gücünü ortaya çıkaran ilgi çekici bir anlatım hazırlıyoruz.

Teknik Mükemmellik Ortaya Çıktı

Mühendislik Hassasiyeti: 350 kg’lık Freeze Dry Cihazının özünde titiz mühendislik yatmaktadır. Her bir bileşen bir başyapıttır ve sonuçta yalnızca ürünleri korumakla kalmayıp aynı zamanda kalitelerini de geliştirerek mükemmellik için yeni bir standart belirleyen bir cihaz ortaya çıkar.

Gelişmiş Vakum Sistemi: Cihazın kalbi gelişmiş vakum sisteminde yatmaktadır. 0,1 milibar kadar düşük vakum seviyelerine ulaşma kapasitesiyle, ürünün özünü korurken nemi ustalıkla gideren yumuşak bir süreç olan süblimasyona elverişli bir ortam yaratır.

Özel Sıcaklık Kontrolü: 350 kg’lık Freeze Dry Cihazı, kullanıcılara titiz sıcaklık kontrolü sağlar. İster hassas botaniklerle ister sağlam etlerle çalışılıyor olsun, -50°C ile 30°C arasındaki sıcaklık aralığı, ürünlerin hassas bir şekilde korunmasını, renklerinin, lezzetlerinin ve besin değerlerinin korunmasını sağlar.

Akıllı Basınç Yönetimi: Cihazın gelişmiş basınç kontrol mekanizması, optimum işleme koşullarını sağlar. Hassas basınç yönetimi sayesinde, ürünün dokusunu ve tadını koruyarak dondurarak kurutma işleminin sorunsuz bir şekilde yürütülmesini sağlar.

Kullanıcı Dostu Arayüz: Korumanın inceliklerinde gezinmek hiç bu kadar sezgisel olmamıştı. Cihaz, kişiselleştirmenin gücünü parmaklarınızın ucuna getiren sezgisel bir dokunmatik ekran arayüzüne sahiptir. Kullanıcı dostu bir şekilde parametreleri zahmetsizce değiştirin, ilerlemeyi izleyin ve gerçek zamanlı güncellemeleri alın.

Çok Yönlü Kurutma Odaları: Çok yönlülük bu cihazın temel taşıdır. Modüler kurutma odalarıyla donatılmış olup, çeşitli ürün türlerine ve parti boyutlarına uyum sağlayarak ihtiyaçlarınıza kusursuz bir şekilde uyum sağlar. Bu uyarlanabilirlik, gelişmiş verimlilik ve üretkenliğe dönüşür.

Ürün Potansiyelinin Kilidini Açmak: Ürünlerinizin raf ömrünü uzatırken, aynı zamanda doğal niteliklerini de büyüttüğünüzü hayal edin. 350 kg Dondurarak Kurutma Cihazı ile sadece muhafaza etmiyorsunuz; Sınırsız potansiyelin kilidini açıyorsunuz. Bu anlatım, cihazı, ürünlerinizin özünü güçlendirecek bir katalizör görevi görüyor.

Mükemmelliğe Yatırım: Cihaz yalnızca bir satın alma işlemi olmaktan çok daha fazlasıdır; mükemmelliğe yapılan bir yatırımdır. 350 kg Freeze Dry Cihazını seçerek, işletmenizi alanınızda öncü olarak konumlandırırken aynı zamanda acil koruma ihtiyaçlarını karşılayan bir teknolojiye yatırım yapmış olursunuz.

Özelleştirme Yoluyla Güçlendirme: Cihazın kullanıcı odaklı tasarımı, koruma sürecini benzersiz spesifikasyonlarınıza göre uyarlamanıza olanak tanır. Bu anlatı, özel çözümler arayan işletmelerde yankı uyandırarak, sonuçlar üzerindeki etkinizin altını çiziyor.

Öncü Verimlilik: Cihazın gelişmiş özellikleri yalnızca dikkat çekici değildir; korumanın geleceğini temsil ediyorlar. Bu teknolojiyi benimseyerek kuruluşunuzu, gelişen pazar dinamiklerine ayak uydurmaya hazır, yenilikçiliğin ön saflarında konumlandırıyorsunuz.

Çözüm

350 kg’lık Freeze Dry Cihazı, sadece bir cihaz olmanın ötesinde; bu, yeni bir koruma çağına açılan bir kapıdır. Teknik mükemmelliği ve kullanıcı odaklı tasarımıyla koruma kavramını yeniden tanımlıyor. Bu cihazı entegre etmek sadece yeniliği benimsemek değildir; ürünlerinizin göz alıcı bir şekilde parlayacağı ve dayanıklı olacağı bir geleceği güvence altına alıyor. Sınırsız koruma potansiyeli alanına hoş geldiniz – 350 kg Dondurarak Kurutma Cihazına hoş geldiniz.

- Avantajları

- Teknik Detaylar

- Opsiyon Listesi

| Standartlara uygun |

| Yüksek verim |

| Kaliteli ekipmanlar |

| Dış etkilere dayanıklı kabin |

| Kolay kurulum ve montaj |

| Kolay bakım |

| Zemin ya da duvara montaj |

| Geniş ürün yelpazesi |

| Komple, hazır ürün |

| Özel modeller ve tasarımlar |

| Kapasite | Buz Tutma Kapasitesi (kg/parti) | 350 kg |

| Yaş Ürün Yükleme Kapasite (kg/parti) | 253 / 351 | |

| Tepsi Ölçüleri | Toplam Tepsi Alanı (m2) | 39 |

| Tepsi Boyutu (mm) | 565*475 | |

| Ürün Tepsi Sayısı (Adet) | 79 | |

| Tepsi Derinliği (mm) | 20 | |

| Elektrik | Güç Tüketimi (kWh) | 32 |

| Voltaj (V) | 300 | |

| Defrost Sistemi | Sıcak Su ( Otomatik ) | |

| VFD | Vakum Pompası | Var |

| Kompresör | Var | |

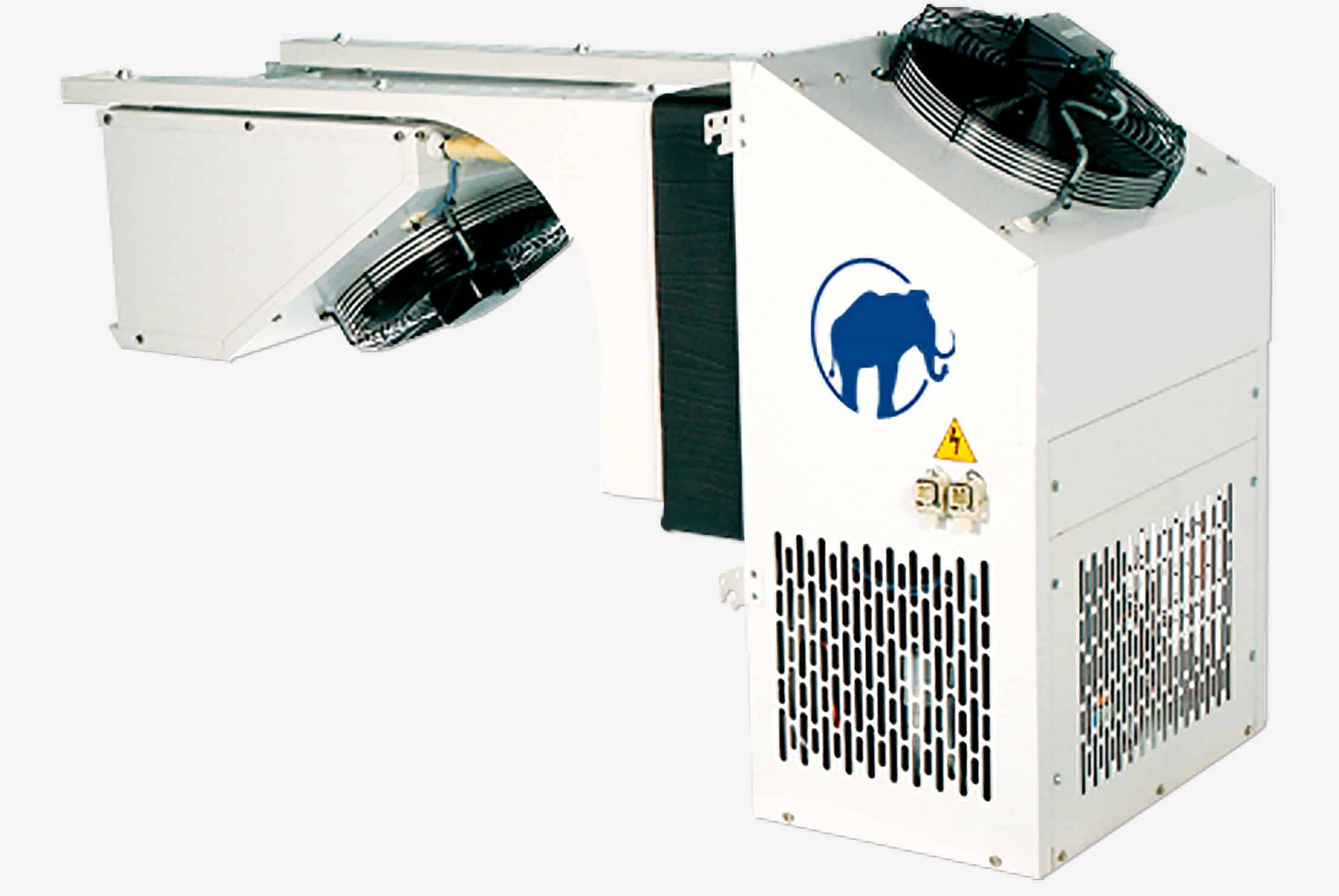

| Kondenser | Fan Hız Kontrol | |

| Ölçüler | Makine Ölçüleri (g*d*y) (mm) (**) | 2456*2507*1775 |

| Makine Yerleşim Alanı (m2) (**) | 8 | |

| Makine Dairesi Alanı ( (m2) (*) | 15 | |

| Raf Sayısı | 15 | |

| Raf Ölçüleri (mm) | 990*1669 | |

| Raf Aralığı (mm) | 29 | |

| Çember Ölçüsü (m) | 1,5 | |

| Vakum | Nihai Vakum Seviyesi (Pa) | 10 ≤ |

| Vakum Pompası | Pfeiffer veya Edwars | |

| Soğutma | Kompresör | Bitzer |

| Soğutucu Gaz | R404A | |

| Soğutma Yolu | Gaz | |

| Yazılım | Yazılım | PLC |

| Uzaktan takip sistemi | Opsiyon | |

| Malzeme | Chamber ( Kazan ) | AISI 304 |

| Tepsi Malzemesi | AISI 304 | |

| Isıtma Raflarının Malzemesi | Alüminyum | |

| Diğer | Ice Kondenser Sıcaklığı (°C) | -45 |

| Raf Sıcaklığı (°C) | max 70 | |

| Isı İletimi | Konveksiyon | |

| Ürün Soğutma Sıcaklığı (°C) | -40 | |

| Ürün Soğutma Yeri | – 40 Soğutma Odası | |

| Isıtma rafları | Glikol + Saf Su | |

| Ürün Yükleme Araba Sayısı | 4 | |

| Raylı Sistem | Yok |

| Elektronik fan devir kontrolu |

| Emiş hattı akümülatörü |

| Alçak-Yüksek basınç presostadı |

| Yağ ayırıcı |

| Akustik ses izolasyonu |